Trusted by global brands

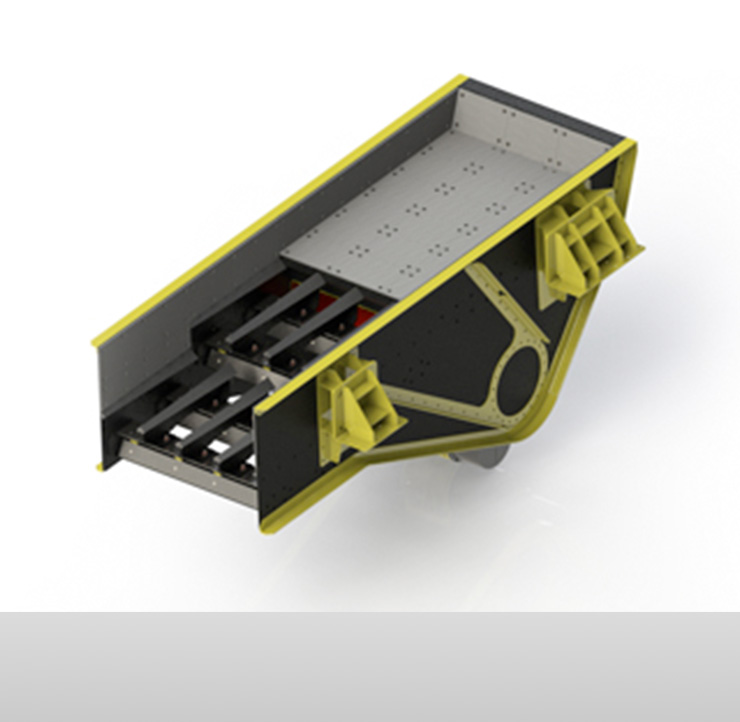

Linear vibrating screens are robust and multi-purpose screening machines, whose entire screening unit is excited to a linear vibration. They are designed as single or multi-deck screening machines. Depending on the application, a wide variety of screen linings, such as wire mesh, perforated plates, welded wire mesh, polyurethane screen mesh, etc. can be installed.

A vibratory feeder is an instrument that uses vibration to "feed" material to a process or machine. Vibratory feeders use both vibration and gravity to move material. Gravity is used to determine the direction, either down, or down and to a side, and then vibration is used to move the material. They are mainly used to transport a large number of smaller objects.

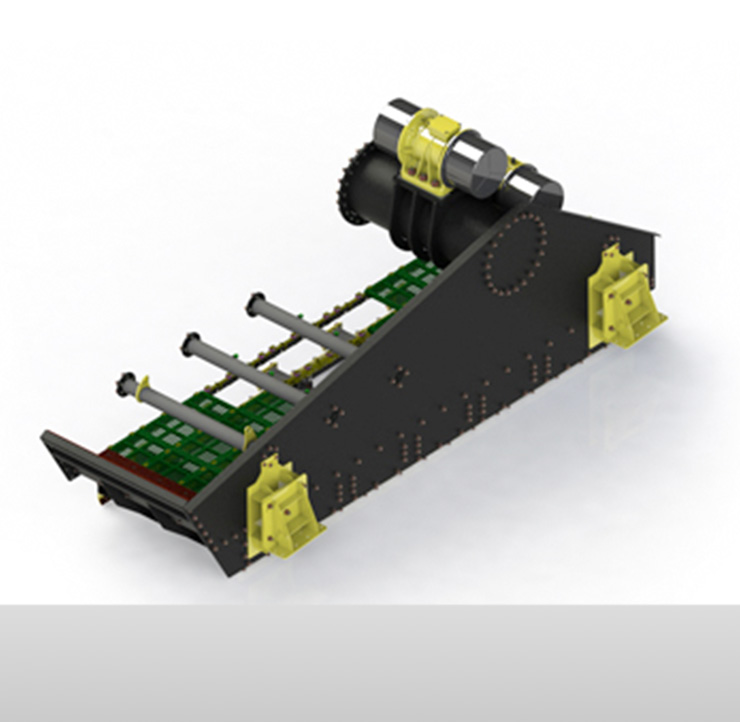

Vibrating Grizzly Feeders are made up of a pan section on one end followed by a series of evenly spaced steel bars at the other. Material is fed to the pan, usually by a loader and carried across by a vibrating force. The vibration also helps move finer particles to the bottom of the load.

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors (floor and overhead) as well.

Hoppers, also called ‘underpans’ or ‘chutes’ are structures used in industrial processes to collect and release particulate matter (such as gravel, coal, ore or waste) onto conveyor belts for transportation. They are constructed in rectangular, round or trough shapes to suit specific loads and materials. Their sides are generally sloped to allow gravity to push the material towards the feeding mouth.

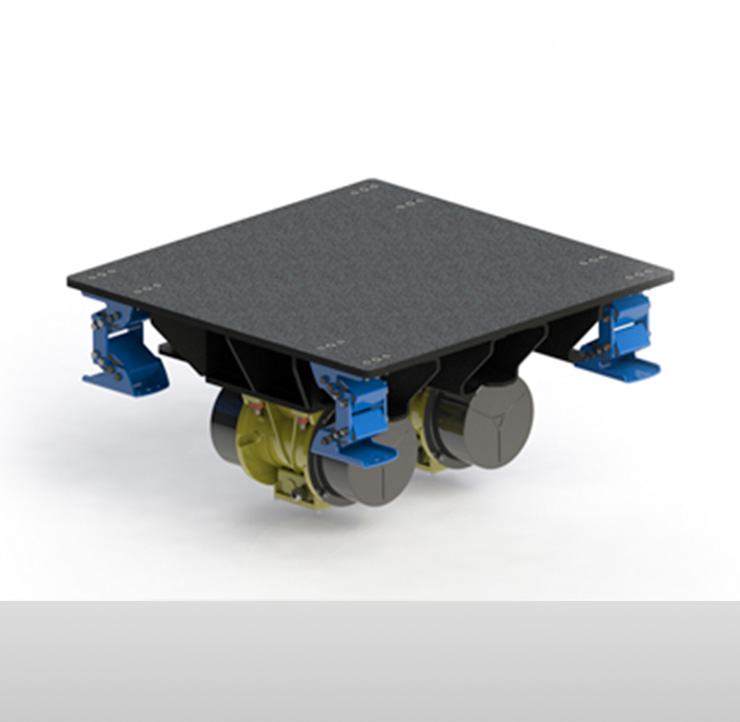

Exciter drives are very expensive and a lot of maintenance is required. In some cases double drive beams that consist out of two Vibrating motors is not enough, for that Quad drive’s is needed.

Mining projects require durable construction materials that can withstand the rigours of mining operations for 25 years or more. In most instances, mining operations are established in some of the harshest weather conditions so all infrastructure needs to be able to withstand dust and sand storms and even hail and flooding. Steel possesses the essential tensile strength and durability to stand up to these extreme conditions at mining sites in South Africa.

Neglecting regular maintenance can lead to costly breakdowns, significantly impacting your plant’s productivity. Our focus is on minimising downtime and maximising productivity, recognizing that efficient maintenance is key to achieving these goals

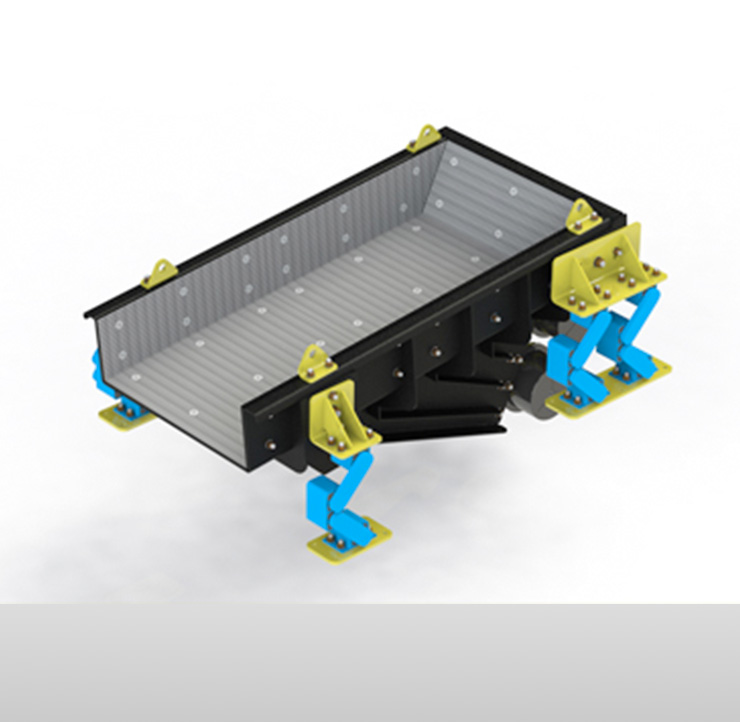

Concrete Vibrating Table is used for consolidating fresh concrete when forming cylinder and beam molds. The table comes with a separate control unit with an on/off switch and rheostat knob to adjust the amplitude of 3,600 vibrations per minute. The power cable to the vibrating table is user-supplied.

Adding {{itemName}} to cart

Added {{itemName}} to cart